From our earliest days in the industry, AHN Biotechnologie GmbH has experienced much success with manufacturing equipment and consumables for laboratories around the world. To complement our success in supplying life science consumables and equipment to end users we have also developed private label manufacturing biotech partnerships with other players in the industry. By leveraging our refined manufacturing processes our various partners have been able to manufacture at scale, delivering high-quality products to their customers. We currently run all private label manufacturing biotech operations at our Nordhausen facility. This modern manufacturing plant is nestled in the green heart of the historic province of Thuringia in Germany. Our manufacturing facility, a spectacle in its own right, is fitted with sophisticated modern equipment that has helped us manufacture at unprecedented scale, delivering customer orders in a timely manner.

Manufacturing And OEM Solutions Company Flyer

Corporate Brochure AHN Biotechnologie

The preferred partner for Private Label Manufacturing Biotechnology

Selecting the right private label manufacturing biotech partner is a fundamental aspect of any product’s success on the market. This is why a large number of our clients establish long-term OEM manufacturing biotech relationships with us. At AHN Biotechnologie GmbH we are committed to providing nothing less than the best service and this is demonstrated by our holistic approach to private label manufacturing biotech. This means recruiting the best talent and creating an optimal manufacturing environment for our teams to do their best work. Our highly qualified team members have deep knowledge and expertise that spans the breadth of private label manufacturing biotech and the relevant supply chain. Each private label manufacturing biotech project that we embark on is staffed by highly competent professionals that will work closely with our clients to ensure successful product launches. The success of our partners is our success, and this is the reason why many of our customers have established long-term OEM manufacturing biotech partnerships with AHN Biotechnologie GmbH.

Selecting the right private label manufacturing biotech partner is a fundamental aspect of any product’s success on the market. This is why a large number of our clients establish long-term OEM manufacturing biotech relationships with us. At AHN Biotechnologie GmbH we are committed to providing nothing less than the best service and this is demonstrated by our holistic approach to private label manufacturing biotech. This means recruiting the best talent and creating an optimal manufacturing environment for our teams to do their best work. Our highly qualified team members have deep knowledge and expertise that spans the breadth of private label manufacturing biotech and the relevant supply chain. Each private label manufacturing biotech project that we embark on is staffed by highly competent professionals that will work closely with our clients to ensure successful product launches. The success of our partners is our success, and this is the reason why many of our customers have established long-term OEM manufacturing biotech partnerships with AHN Biotechnologie GmbH.

Spacious facility for OEM Manufacturing Biotech

As highlighted above, our private label manufacturing biotech manufacturing facility features advanced technology for high throughput production. Unlike some other OEM manufacturing biotech facilities, we take pride in investing in processes that work so as to make them better. This is the reason why we recently completed our largest facility upgrade ever. The newly upgraded facility boasts of a massive 1600m$^2$ production area. This space has allowed us to accommodate advanced robotic platforms that have increased our plastic consumables output. The facility also caters for the production of sterile and contaminant-free products for sensitive applications by reserving 1000m$^2$ for cleanroom production. Approximately 40% of our cleanroom space is class 8 and the other 60% is class 9. Additionally, we have demarcated 80% (~480m$^2$) of the assembly area as the dedicated space for cleanroom assembly, ensuring that quality principles are always upheld. An additional 3000m$^2$ of floor space is used for storage, half of which holds sales stock.

As highlighted above, our private label manufacturing biotech manufacturing facility features advanced technology for high throughput production. Unlike some other OEM manufacturing biotech facilities, we take pride in investing in processes that work so as to make them better. This is the reason why we recently completed our largest facility upgrade ever. The newly upgraded facility boasts of a massive 1600m$^2$ production area. This space has allowed us to accommodate advanced robotic platforms that have increased our plastic consumables output. The facility also caters for the production of sterile and contaminant-free products for sensitive applications by reserving 1000m$^2$ for cleanroom production. Approximately 40% of our cleanroom space is class 8 and the other 60% is class 9. Additionally, we have demarcated 80% (~480m$^2$) of the assembly area as the dedicated space for cleanroom assembly, ensuring that quality principles are always upheld. An additional 3000m$^2$ of floor space is used for storage, half of which holds sales stock.

Only the best quality materials for Private Label Manufacturing Biotechnology

The key ingredient for most of our private label manufacturing biotech plastic consumables is polypropylene. To ensure high-quality end-products we start with premium raw materials. We only work with responsibly sourced raw materials from the best suppliers in the industry. This helps us ensure that we do our part to encourage fair production. Additionally, by working with the best suppliers we can make sure that each grain of polypropylene is manufactured to stringent specifications. This quality control check allows our OEM lab use plastic pipette tips and other plastic consumables to have dependable performance, making sure that customers can expect similar results across different product batches. Additional quality control checks on raw materials limit the probability of common contaminants entering the private label manufacturing biotech production chain. As a result, we can confidently say that our OEM lab use plastic pipette tips and plastic consumables are free of common contaminants such as human/nonhuman DNA, enzymes (DNases and RNases), PCR inhibitors, and pyrogens among others. Our raw materials are also certified free of softening agents, antistatic agents, biocides, as well as other common bioactive additives.

The key ingredient for most of our private label manufacturing biotech plastic consumables is polypropylene. To ensure high-quality end-products we start with premium raw materials. We only work with responsibly sourced raw materials from the best suppliers in the industry. This helps us ensure that we do our part to encourage fair production. Additionally, by working with the best suppliers we can make sure that each grain of polypropylene is manufactured to stringent specifications. This quality control check allows our OEM lab use plastic pipette tips and other plastic consumables to have dependable performance, making sure that customers can expect similar results across different product batches. Additional quality control checks on raw materials limit the probability of common contaminants entering the private label manufacturing biotech production chain. As a result, we can confidently say that our OEM lab use plastic pipette tips and plastic consumables are free of common contaminants such as human/nonhuman DNA, enzymes (DNases and RNases), PCR inhibitors, and pyrogens among others. Our raw materials are also certified free of softening agents, antistatic agents, biocides, as well as other common bioactive additives.

A modern warehouse for OEM Manufacturing Biotech

Once the raw materials are delivered to our warehouse, they are sorted and stored according to specific quality control procedures. This allows us to track the movement of raw materials through the production chain for better traceability and quality auditing. Our quality control specialists conduct routine audits and inspections to make sure that all the polypropylene stocks are at par or better than our strict quality standards. By conducting these audits, warehouse staff are always ready to catch potential issues early, averting potential production delays that can cause inconveniences for our partners. When customers request special raw materials to be used for their OEM lab use plastic pipette tips, the supplies are sorted and stored separate from other raw materials. This limits the possibility of cross-contamination of raw materials and ensures our production quality remains the best on the market. By maintaining world-class standards, our warehouse helps us retain indefatigable production efficiency and untainted product quality.

Once the raw materials are delivered to our warehouse, they are sorted and stored according to specific quality control procedures. This allows us to track the movement of raw materials through the production chain for better traceability and quality auditing. Our quality control specialists conduct routine audits and inspections to make sure that all the polypropylene stocks are at par or better than our strict quality standards. By conducting these audits, warehouse staff are always ready to catch potential issues early, averting potential production delays that can cause inconveniences for our partners. When customers request special raw materials to be used for their OEM lab use plastic pipette tips, the supplies are sorted and stored separate from other raw materials. This limits the possibility of cross-contamination of raw materials and ensures our production quality remains the best on the market. By maintaining world-class standards, our warehouse helps us retain indefatigable production efficiency and untainted product quality.

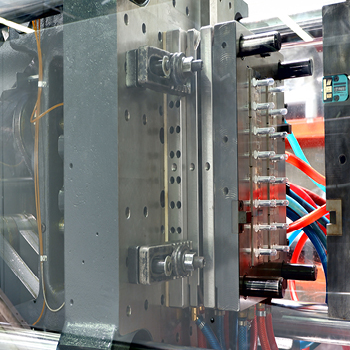

Injection Molding – High-tech Private Label Manufacturing Biotechnology

From the warehouse, the premium quality raw materials for OEM lab use plastic pipette tips manufacturing enter the production facility. The first step of production is injection molding where the polypropylene is transformed into OEM lab use plastic pipette tips that are supplied to consumers. Using high-efficiency, thermally controlled machinery the raw materials are rapidly heated to their melting temperature. This step is carefully controlled to ensure even thermal distribution to minimize thermal islands that can compromise product quality. Once the ideal temperature is achieved, our high-tech production machinery directs the molten polypropylene to precision fabricated pipette tip molds. Each mold is carefully constructed to ensure the dimensions and volume of all OEM lab use plastic pipette tips are within strict specifications. This, like other steps, ensures that OEM lab use plastic pipette tips manufactured by AHN Biotechnologie have similar performance characteristics across different product batches. By controlling the quality of our injection molds and the pouring rates we ensure we remain a dependable private label manufacturing biotech partner.

From the warehouse, the premium quality raw materials for OEM lab use plastic pipette tips manufacturing enter the production facility. The first step of production is injection molding where the polypropylene is transformed into OEM lab use plastic pipette tips that are supplied to consumers. Using high-efficiency, thermally controlled machinery the raw materials are rapidly heated to their melting temperature. This step is carefully controlled to ensure even thermal distribution to minimize thermal islands that can compromise product quality. Once the ideal temperature is achieved, our high-tech production machinery directs the molten polypropylene to precision fabricated pipette tip molds. Each mold is carefully constructed to ensure the dimensions and volume of all OEM lab use plastic pipette tips are within strict specifications. This, like other steps, ensures that OEM lab use plastic pipette tips manufactured by AHN Biotechnologie have similar performance characteristics across different product batches. By controlling the quality of our injection molds and the pouring rates we ensure we remain a dependable private label manufacturing biotech partner.

Automated Custom Manufacturing Biotech

A key differentiator of our private label manufacturing biotech processes is our huge investment in process automation. While this is an expensive undertaking, it has allowed us to increase our production efficiency while reducing the incidence of human error. Additional benefits of our automated OEM manufacturing biotech processes are reduced risk of contamination, lower production costs, and shorter production runs per batch. Our Nordhausen based production facility is equipped with a total of 15 advanced robotic workstations that carry the bulk of the production load. In addition to these automated workstations, we have an automated cleanroom facility that processes all sterile and contaminant-free products including OEM lab use plastic pipette tips. This allows us to certify each “contaminant-free” product with confidence, knowing that it is exactly what we designed it to be for our private label manufacturing biotech partners. All our products are also molded with the aid of automated robotic processes that are routinely audited for quality purposes. Thanks to our continued investment in automation technologies, we continue to rank well among the best private label manufacturing biotech consumables manufacturers.

A key differentiator of our private label manufacturing biotech processes is our huge investment in process automation. While this is an expensive undertaking, it has allowed us to increase our production efficiency while reducing the incidence of human error. Additional benefits of our automated OEM manufacturing biotech processes are reduced risk of contamination, lower production costs, and shorter production runs per batch. Our Nordhausen based production facility is equipped with a total of 15 advanced robotic workstations that carry the bulk of the production load. In addition to these automated workstations, we have an automated cleanroom facility that processes all sterile and contaminant-free products including OEM lab use plastic pipette tips. This allows us to certify each “contaminant-free” product with confidence, knowing that it is exactly what we designed it to be for our private label manufacturing biotech partners. All our products are also molded with the aid of automated robotic processes that are routinely audited for quality purposes. Thanks to our continued investment in automation technologies, we continue to rank well among the best private label manufacturing biotech consumables manufacturers.

Impeccable quality control – An essential aspect of Private Label Manufacturing Biotechnology

As AHN Biotechnologie GmbH our OEM manufacturing biotech partnerships are built on the foundation trust and good manufacturing practice. Because of this, we invest heavily in quality control and quality assurance processes that help us to maintain a world-class approach to private label manufacturing biotech. Our manufacturing facility has held DIN EN ISO 9001:2015 certification for over 15 years and we continue to hold ourselves to a high standard of quality in all our private label manufacturing biotech. For polypropylene products such as OEM lab use plastic pipette tips, we have specific quality management systems in place that are compliant with international best practices. For example, we measure the optical density of each batch of OEM lab use plastic pipette tips to make sure that they meet our strict guidelines for clarity. Additionally, we check for burrs to ensure all OEM lab use plastic pipette tips have unrestricted openings, and we also assess the shape to verify consistency of product dimensions across batches. By holding ourselves to lofty quality standards we allow our partners to expect and receive good products from our private label manufacturing biotech partnerships.

As AHN Biotechnologie GmbH our OEM manufacturing biotech partnerships are built on the foundation trust and good manufacturing practice. Because of this, we invest heavily in quality control and quality assurance processes that help us to maintain a world-class approach to private label manufacturing biotech. Our manufacturing facility has held DIN EN ISO 9001:2015 certification for over 15 years and we continue to hold ourselves to a high standard of quality in all our private label manufacturing biotech. For polypropylene products such as OEM lab use plastic pipette tips, we have specific quality management systems in place that are compliant with international best practices. For example, we measure the optical density of each batch of OEM lab use plastic pipette tips to make sure that they meet our strict guidelines for clarity. Additionally, we check for burrs to ensure all OEM lab use plastic pipette tips have unrestricted openings, and we also assess the shape to verify consistency of product dimensions across batches. By holding ourselves to lofty quality standards we allow our partners to expect and receive good products from our private label manufacturing biotech partnerships.

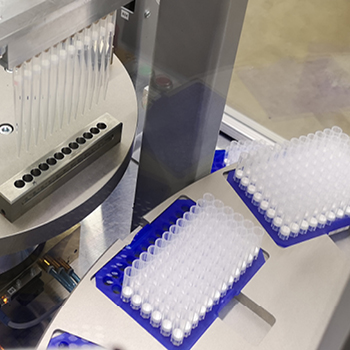

Packaging – The last mile at our OEM Manufacturing Biotech facility

When all the quality checks are passed, the OEM lab use plastic pipette tips are transferred to the various assembly stations. Each station is equipped with modern machines that work with speed and extraordinary precision – making sure that each pipette tip is inserted in its rack spot perfectly. The assembly machines at our facility are designed to adapt to the different packaging needs of our various private label manufacturing biotech partners. This allows us to fulfill different packaging demands without overly adjusting our workflow. With this manufacturing approach, all our customers receive their custom orders in a timely manner. In addition to their role in increasing productivity, the assembly robots help us maintain high quality in each batch of OEM lab use plastic pipette tips.

When all the quality checks are passed, the OEM lab use plastic pipette tips are transferred to the various assembly stations. Each station is equipped with modern machines that work with speed and extraordinary precision – making sure that each pipette tip is inserted in its rack spot perfectly. The assembly machines at our facility are designed to adapt to the different packaging needs of our various private label manufacturing biotech partners. This allows us to fulfill different packaging demands without overly adjusting our workflow. With this manufacturing approach, all our customers receive their custom orders in a timely manner. In addition to their role in increasing productivity, the assembly robots help us maintain high quality in each batch of OEM lab use plastic pipette tips.

Flexible Custom Manufacturing Biotech

As we near the conclusion, we thought it’s necessary to highlight the flexibility of our manufacturing process for OEM lab use plastic pipette tips. There are several steps in the production chain that are adaptable to meet the different private label manufacturing biotech requirements of our various partners. Firstly, most of our machinery and technologies are compatible with a wide variety of product designs. This allows us to service multiple client contracts at the same time without compromising the quality of OEM lab use plastic pipette tips. This also minimizes downtime by making sure all customer orders are fulfilled in a timely manner. Secondly, the machines in the production facility are compatible with a broad range of mold designs. When customers submit specific design requests, our production team can rapidly incorporate the appropriate molds in the production line and continue production of OEM lab use plastic pipette tips without any significant decrease in the output. Lastly, when our partners have specific tooling requirements, we have systems in place that allow for seamless incorporation of the custom requirements into existing infrastructure. By fully embracing flexibility in the manufacturing of OEM lab use plastic pipette tips we have been able to serve a growing customer base without compromising their product specifications.

As we near the conclusion, we thought it’s necessary to highlight the flexibility of our manufacturing process for OEM lab use plastic pipette tips. There are several steps in the production chain that are adaptable to meet the different private label manufacturing biotech requirements of our various partners. Firstly, most of our machinery and technologies are compatible with a wide variety of product designs. This allows us to service multiple client contracts at the same time without compromising the quality of OEM lab use plastic pipette tips. This also minimizes downtime by making sure all customer orders are fulfilled in a timely manner. Secondly, the machines in the production facility are compatible with a broad range of mold designs. When customers submit specific design requests, our production team can rapidly incorporate the appropriate molds in the production line and continue production of OEM lab use plastic pipette tips without any significant decrease in the output. Lastly, when our partners have specific tooling requirements, we have systems in place that allow for seamless incorporation of the custom requirements into existing infrastructure. By fully embracing flexibility in the manufacturing of OEM lab use plastic pipette tips we have been able to serve a growing customer base without compromising their product specifications.

Partner with us in your next Private Label Manufacturing Biotechnology adventure

Each year there are many novel and exciting discoveries that create new research opportunities in the Life Sciences and Health Sciences. These novel and potentially impactful research opportunities help human beings increase our collective knowledge of the planet and beyond. By partnering with AHN Biotechnologie GmbH you can supply the tools that enable scientists and clinicians at the leading edge of discovery do their best work. Each OEM manufacturing biotech partnership that we forge is treated with the utmost confidentiality. This allows your organization to get all the credit for your vision for Life and Health Sciences research tools designed for the 21st century and beyond. You can count on AHN Biotechnologie GmbH to support your vision from initial design right through to final production. We offer production transparency as well as flexibility, allowing us to adapt to your specific private label manufacturing biotech needs. Lastly, we are committed to nothing less than world-class OEM manufacturing biotech quality. When you can reach the world, why settle for less. By partnering with AHN Biotechnologie GmbH you are part of a winning team. Click here to connect with a representative today and get started on your journey to private label manufacturing biotech success with AHN Biotechnologie GmbH.

Each year there are many novel and exciting discoveries that create new research opportunities in the Life Sciences and Health Sciences. These novel and potentially impactful research opportunities help human beings increase our collective knowledge of the planet and beyond. By partnering with AHN Biotechnologie GmbH you can supply the tools that enable scientists and clinicians at the leading edge of discovery do their best work. Each OEM manufacturing biotech partnership that we forge is treated with the utmost confidentiality. This allows your organization to get all the credit for your vision for Life and Health Sciences research tools designed for the 21st century and beyond. You can count on AHN Biotechnologie GmbH to support your vision from initial design right through to final production. We offer production transparency as well as flexibility, allowing us to adapt to your specific private label manufacturing biotech needs. Lastly, we are committed to nothing less than world-class OEM manufacturing biotech quality. When you can reach the world, why settle for less. By partnering with AHN Biotechnologie GmbH you are part of a winning team. Click here to connect with a representative today and get started on your journey to private label manufacturing biotech success with AHN Biotechnologie GmbH.